Plant / Machinery Relocation

Machine Relocation We provide our clients quality services for Machine Shifting from one location to another location in plants. Backed by a strong and experienced team of personnel, these Factory Machine Shifting Services are carefully handled with full stress given to demands and specifications of the clients. Our services are appreciated by our clients for reliability, timeliness and are offered at most competitive prices

Plant Relocation We are engaged in offering valuable services for Plant Shifting, that are undertaken by our qualified and experienced team of professionals. Facilitated with quality machines, we can easily shift plants from one location to another. These Industrial Relocation Services are provided by us keeping in mind the quality aspect, time limits and other specifications of the clients

Factory Relocation We are engaged in offering valuable services for Factory Shifting from one place to another place in any state. We maintain geometry and accuracy of machine after assembly same as before dis-assembly.

ANNUAL MAINTENANCE CONTRACTS

Yuvitech Offeres Annual Maintenance Contract for your complete electrical system including Power & Distribution Transformers, HT/LT Panels, Bus Duct, and Earthing. Periodic maintenance is required for trouble free operations and uninterrupted supply of power. Monthly, Quarterly, Bi-annual, Annual visits are planned by our service engineers depending on the services availed by the customers. Also if any faults or major breakdown are observed we provide immediate assistance ensuring zero breakdown

Yuvitech’sAMC Benefits :

- Increases the life of your Electrical system

- Better Returns on Investment

- Prevention from Sudden Breakdown

- Cost-effective

- In case of damage, repair cost or maintenance cost is very less than the cost of a new Equipment

- Regular maintenance of Equipment will ensure no major damage occurs for a longer period

- Healthy life of your Equipments

- Your Electrical System is a major and costly part of any electrical transmission and distribution system.

- A healthy equipment can assure a healthy electrical system

- Optimum performance by your Electrical equipment

PREVENTIVE MAINTENANCE SERVICES

1. The preventive maintenance can be defined as a time based maintenance. Preventive maintenance aims to prevent the occurrence of failure. In addition, it aims to guarantee long lifetime of the asset. It is recommended to get the preventive maintenance of your electrical installations done every year.

2. Preventive maintenance (PM), which includes operational & planned maintenance, protects property and safeguards production. PM is a crucial part of loss control activities. PM of electrical equipment monitors the deterioration of equipment and components and detects or predicts insulation, equipment, and system flaws. PM reduces the frequency of losses. As with other loss control techniques, varying degrees of control are possible.

CONDITION MONITORING OR PREDICTIVE MAINTENANCE SERVICES

Condition Monitoring or Predictive Maintenance services mainly focuses on the detection of faults inside the electrical systems, which are created from gradual deterioration. The significance of a condition monitoring is in that it allows for the early identification of developing faults such as arcing before resulting in sudden great damage or failure.

CCondition monitoring of a costly and critical equipments / assets are aimed to: -Detect faults at incipient stage and avoid catastrophic faults, and -Reduce maintenance costs by doing condition based rather than time-based maintenance.

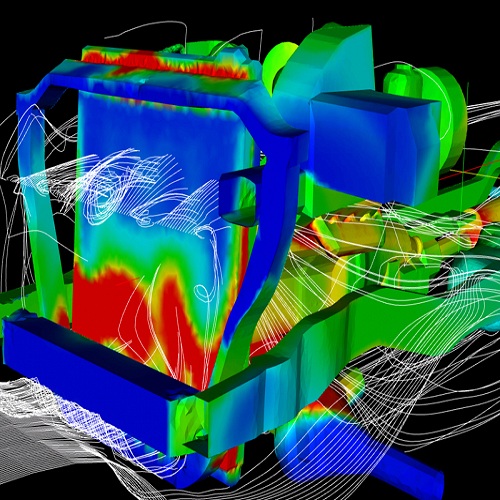

Condition monitoring by thermal analysis

Thermal analysis of transformers can provide useful information about their conditions and can be used to detect the inception of any fault . Most of the faults cause change in the thermal behavior of transformers. Abnormal conditions can be detected by analyzing HST (hot spot temperature) or Thermograph. The HST is one of the major limiting factors that affect the useful life of the power transformer and its loading. The HST differential is defined by industrial standards (NEMA and ANSI) for each insulation class (type and temperature rating of insulation used on windings). Obviously, the HST is the limiting temperature for a transformer’s insulation system.

Abnormal heating associated with high resistance or excessive current flow is the main cause of many problems in electrical systems. Infrared thermography allows us to see these invisible thermal signatures of impending damage before the damage occurs. When current flows through an electric circuit, part of the electrical energy is converted into heat energy. This is normal. But, if there is an abnormally high resistance in the circuit or abnormally high current flow, abnormally high heat is generated which is wasteful, potentially damaging and not normal. Thermal imagers enable us to see the heat signatures associated with high electrical resistance long before the circuit becomes hot enough to cause an outage or explosio

Condition monitoring by dissolve gas analysis

Dissolved gas analysis is a traditional way for monitoring insulation condition; concentration types and production rates of generated gasses can be used for fault diagnosis. Nevertheless, the concentration of these gases increases in the presence of an abnormality (fault) such as thermal and partial discharge and arcing faults. The combustible gases are produced when insulating oils and cellulose materials are subjected to excessive electrical or thermal stresses. Multiple dissolved gas analysis tests should be taken over time so that the rate of increase of fault gases can be monitored, through which the progress of the fault can be monitored.

Condition monitoring by Cable Fault Location

Faults are the “natural enemy“ of reliability. A cable fault can cause an expensive unplanned outage or delay the commissioning of a new part of the network, so they need to be found and rectified quickly to enable new connections or restore the consumers’ supply. Engineers can find underground cable faults by accurately determining the distance to the fault (prelocation) and subsequently determining the exact location of the fault (pinpointing). Cable fault location on power and communication cables is a specialised area of expertise, but Megger fault locators make it simple: each instrument’s intuitive operation guides you through the fault finding process. Innovative Megger products make it possible for the user to quickly find and localise cable faults without causing damage to fault-free parts of the cable, using well-defined fault finding techniques and the appropriate test equipment

Your benefits of Condition based Maintenance

- Reduced lifecycle costs

- Avoidance of faults and penalties

- Increased and secure energy supply

- Optimized asset performance

Electrical Equipment Repairs and Upgrades

- Transformer/LT Panel/ACB/VCB repairs has been part of the business this is our guarantee of a fast quality service.

- Yuvitechhas vast experience in any electrical equipment repair and/or modification you may need. Our skilled, Service Centre trained technicians have performed routine maintenance, upgrading and retrofitting thousands of LTC’s/ACB/VCB/Transformer/LT Panel/Distribution Panel from every make and model.

- Yuvitech can bring any needed parts to your site to be able to handle any needed repairs, upgrades or replacement of your equipment.

- A full design service enables us to up-grade equipment to take account of modern superior insulation systems.

- Silica gel supply and replace (environmental friendly) along with silica gel breathers.

- On load and off load tap changer servicing.

- Complete oil changes carried out together with oil leak transformer repair on site along with any transformer gasket changes

RELAY COMMISSIONING, TESTING & CALIBRATION

A relay is an automated protection device designed to trip a circuit breaker whenever a fault is detected. With usage the connections of relay gets deteriorated or contaminated with carbon particles, etc. Therefore it’s the interest of both the end user as well the manufacturer to check the behavior of relay after time intervals

- Installation & Testing of all types of Digital &Analog Relays.

- Measurements of live CT currents, checking of relay wiring & its tightness.

- Testing of relays by Primary & Secondary Injection Tests.

- Calibration of all types of relays to verify if the relay operation is within its trip time and pick up current tolerances.

- Relay Programming, Relay setting and Scheme checking.

- Alarm test-checks the functioning of Alarm, which is to notify of the errors in the internal circuit.

Technical Manpower Supply

In our business organizations, we are offering a comprehensive assortment of Technical Manpower Deputation Services. In tandem with the variable needs and necessities of our customers, these offered services could be accomplished from us in between the guaranteed period of time.

Engineering and Project Management

- Layouts for the power distribution system &Single line diagrams.

- Lighting scheme design for internal and external lighting, lighting layouts with SLDs. Selection of fixtures and detailing of mounting

- Detail engineering & layout drawings for lightening protection &earthing systems

- Detailing and drawings for Cable Tray layouts, Earthing, Power & Lighting Drawings

- Preparation of Technical specification for equipment and works. Preparation of bill of quantities and estimates based on BOQ and Specs.

- Floating Inquiries / Tenders consisting of:

- General terms of contract

- Technical specifications

- Schedule of quantities

- Drawings

- Technical and commercial comparison of quotes for above recommendation, negotiations, order drafts etc

- Preparation of work schedule and programs based on available information and inputs from clients

- We optimize the electrical equipment cost with valuable engineering using proper code/standards and engineering software.

Project Management

Yuvitech Engineering focuses on proactively engaging and leading clients through every phase of a project, from planning through commissioning.